Pressed Scaffolding Coupler

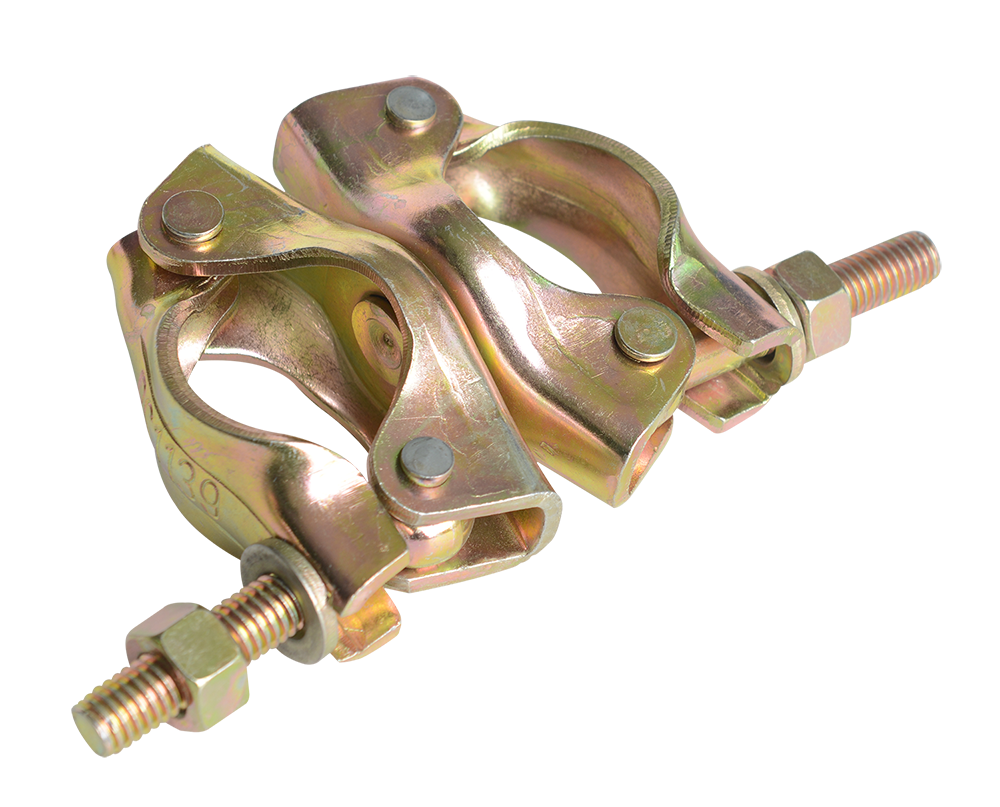

- Material: Q235

- Size: 48.3mm* 48.3mm,48.3mm* 60.3mm

- Surface finish: electric galvanized

- Standard: BS1139, EN74

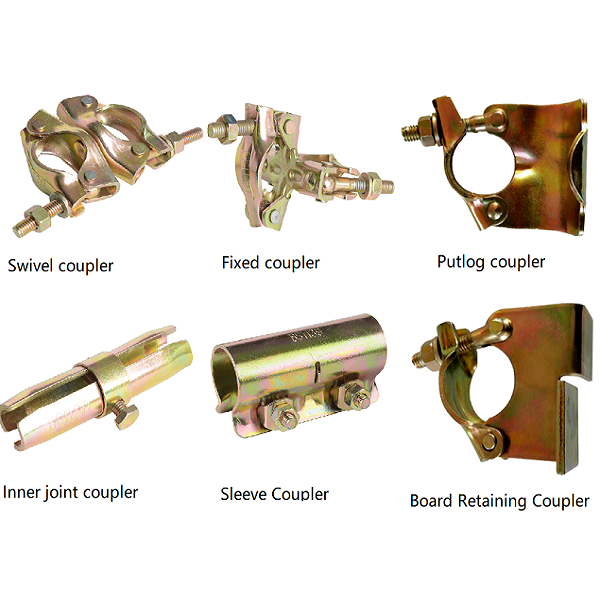

- Types: British swivel coupler, British fixed coupler, Board Retaining coupler, Putlog coupler, Sleeve coupler,

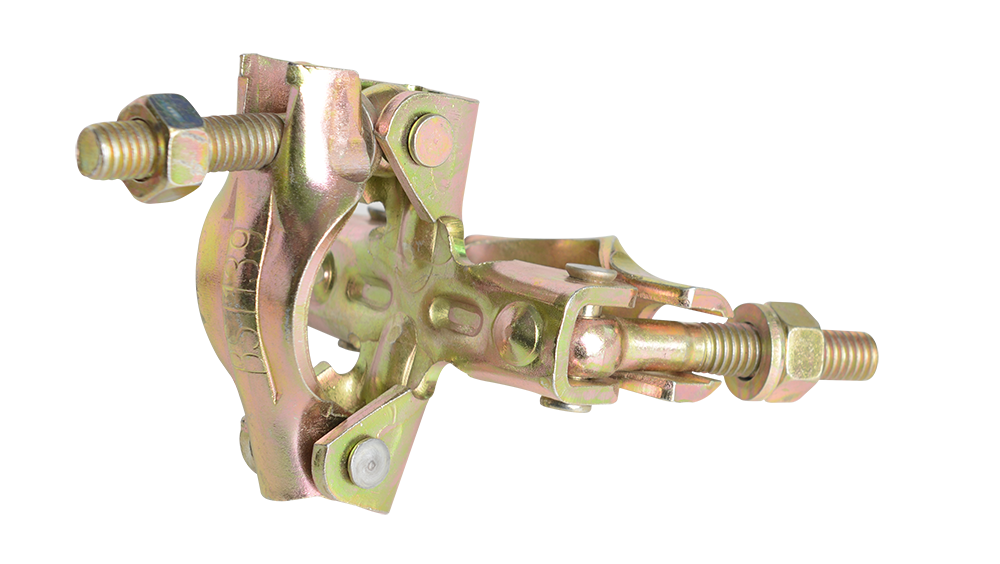

- Inner joint pin,110° double coupler, 110° swivel coupler, 90° swivel coupler,90° double coupler

- Packing: 25pcs/Woven bags, 50bags/pallets or as customer required.

| Distription | Thickness | U.W | Quantity of ONE 20’GP |

| Swivel Coupler | 4.5*4.75mm | 0.99 | 23500 |

| Fixed coupler /Double Coupler | 4.75mm | 0.82kg | 25000 |

| Putlog Coupler | 4.75mm | 0.57kg | 35000 |

| Inner Joint Pin | 4.5mm | 0.7kg | 35000 |

| Sleeve Coupler | 3.5mm | 1.0kg | 20736 |

| Board Retaining | 4.75mm | 0.56kg | 35000 |

Reviews

There are no reviews yet.